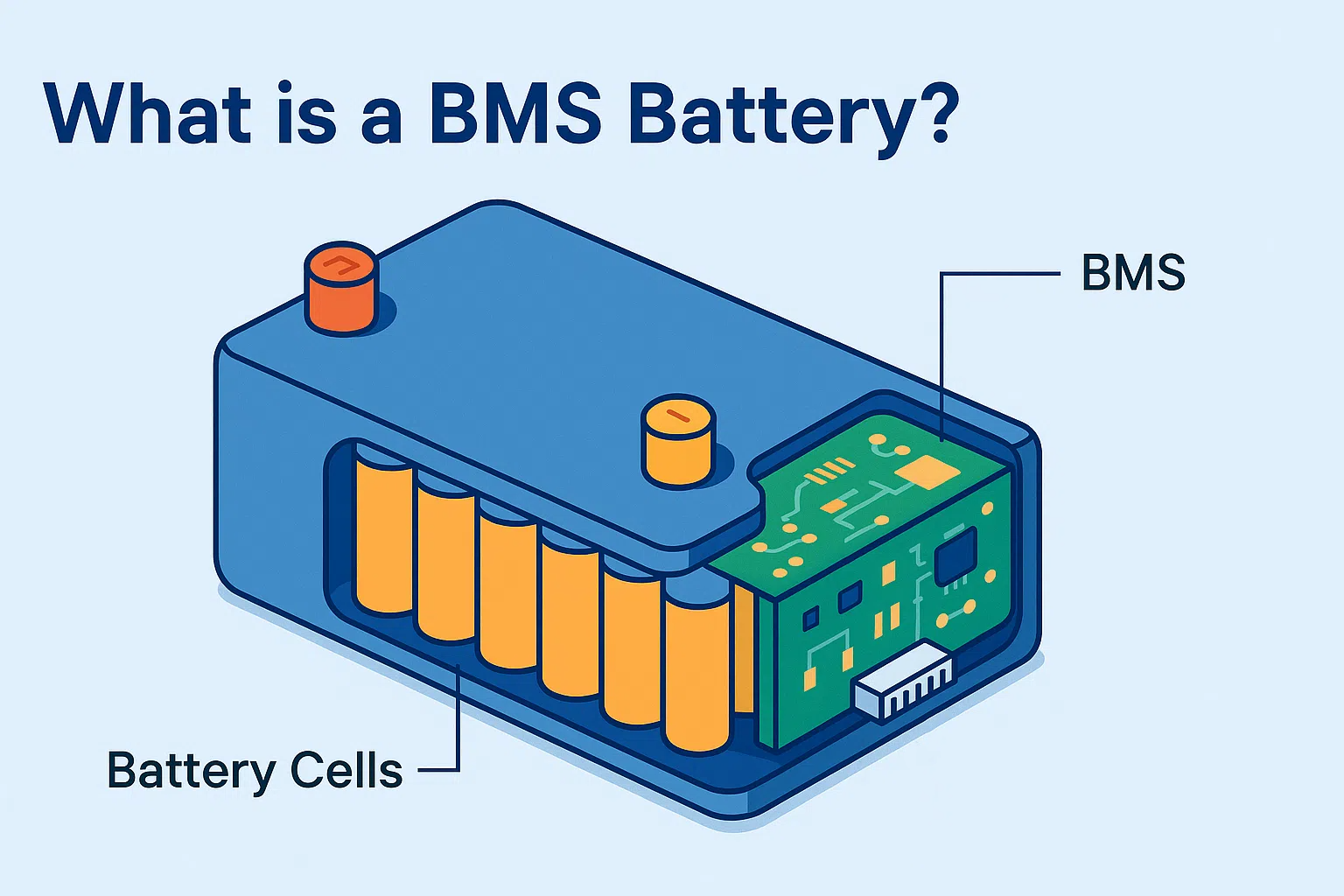

What Is a BMS Battery?

A Battery Management System (BMS) is a critical electronic system integrated into rechargeable battery packs, especially lithium-ion batteries, to ensure their optimal performance, safety, and longevity. It acts as the "brain" of the battery pack by continuously monitoring and managing various parameters such as voltage, current, temperature, and state of charge (SoC), thereby preventing dangerous conditions and maximizing battery life. This article provides an in-depth exploration of BMS, addressing its functions, necessity, and common user queries.

What is BMS on a battery?

A Battery Management System (BMS) is an electronic system connected to a rechargeable battery pack (especially multi-cell packs) that manages its state, ensures its safety, optimizes its performance, and potentially communicates with external devices. Think of it as an intelligent supervisor constantly monitoring and controlling the battery's health and operation. Key functions include:

●Cell Monitoring: Tracks voltage, temperature, and current of individual cells.

●Balancing: Ensures all cells charge/discharge evenly.

●Protection: Prevents overcharging, over-discharging, and overheating.

●State of Charge (SOC) Estimation: Calculates remaining battery capacity.

●Communication: Relays data to external systems (e.g., via Bluetooth or CAN bus).

Do all lithium batteries have BMS?

Not all lithium batteries include a BMS. Single-cell lithium batteries, such as those in small devices like smartphones, often rely on simpler protection circuits integrated into the device or charger. However, multi-cell lithium battery packs, such as those in EVs, e-bikes, or solar storage systems, almost always incorporate a BMS to manage the complexity of multiple cells. The absence of a BMS in multi-cell setups can lead to safety risks and reduced battery life.

Why is BMS required?

The BMS is not just a convenience, and it’s a safety-critical system. Without a BMS:

●Safety Hazards: Overcharging, over-discharging, or overheating can cause cells to vent flammable electrolytes, swell, catch fire, or even explode (a phenomenon called thermal runaway). The BMS is the primary safety barrier against these events.

●Reduced Lifespan: Repeatedly operating cells outside their ideal voltage or temperature ranges drastically shortens their lifespan. Cell imbalance also reduces usable capacity and stresses individual cells, leading to premature failure.

●Poor Performance: Without balancing, the pack's capacity becomes limited by the weakest or lowest-charged cell during discharge, and charging is limited by the highest-charged cell. The BMS maximizes usable capacity.

●Irreversible Damage: Deeply discharging a lithium cell below its minimum voltage threshold can cause permanent damage, rendering it unusable.

Do I need a BMS for each battery?

In a battery pack with multiple cells, a single BMS typically manages the entire pack, not individual cells. However, if you have multiple independent battery packs, each pack requires its own BMS to monitor and protect its cells. For example, in an EV with multiple battery modules, each module may have a dedicated BMS, or a centralized BMS may oversee all modules, depending on the system design.

Can I use lithium battery without BMS?

Using a lithium battery without a BMS is generally not recommended for multi-cell packs due to safety and performance concerns. Single-cell batteries may function without a dedicated BMS if the device or charger includes protection circuitry. For any application involving multiple lithium cells, a BMS is considered essential for safety and proper function.

What is the difference between a battery controller and a BMS?

A Battery Management System (BMS) is a comprehensive system that monitors, protects, balances, and reports on the battery pack’s status. A battery controller may refer to a simpler device or circuit that controls charging or discharging but does not provide the full range of monitoring, balancing, and safety functions that a BMS offers. In essence, the BMS is a more advanced and integrated system designed for safety and performance optimization

Does a BMS have a fuse?

A BMS provides electronic over-current and short-circuit protection, usually by using MOSFETs (transistors) to switch off the connection between the battery cells and the external terminals if unsafe currents are detected. However, a BMS itself is typically not a fuse. A fuse is a passive, one-time protection device that physically melts and breaks the circuit during a severe overcurrent event.

Can I charge battery without BMS?

Charging a lithium battery without a BMS is risky. The charger alone cannot monitor individual cell voltages or temperatures, so it cannot prevent overcharging of single cells within a pack. The BMS ensures that charging stops or is adjusted if any cell reaches unsafe voltage or temperature levels, preventing damage or fire risk.

Can you overcharge a lithium battery with a BMS?

A properly functioning BMS is specifically designed to prevent overcharging. When any cell within the pack reaches the pre-set maximum safe voltage limit, the BMS should signal the charger (if possible) or, more fundamentally, open the charging circuit (using its MOSFETs) to stop the charge current from flowing into the battery pack. However, a faulty BMS or incorrect configuration may fail. Regular testing is essential.

How to check if BMS is working?

To verify BMS functionality:

●Measure voltages across individual cells – ensure they’re balanced

●Use a BMS communication interface (e.g., UART, I2C, CAN bus) to read diagnostic data

●Test protection behavior by simulating overcharge/overdischarge (carefully)

●Observe LED indicators or diagnostic apps (for smart BMS units)

●For critical systems, use a BMS with data logging and alerts.

How do I match my BMS to my battery?

Choosing the right BMS involves matching it to your battery’s specifications:

●Cell Configuration: Ensure the BMS supports the number of cells in series (e.g., 4S for four cells) and parallel (if applicable).

●Voltage Rating: The BMS must handle the battery’s nominal and maximum voltages (e.g., 14.8V nominal, 16.8V max for a 4S lithium-ion pack).

●Current Rating: Select a BMS with a continuous current rating equal to or greater than the battery’s maximum discharge/charge current.

●Chemistry: Confirm compatibility with your battery type (e.g., Li-ion, LiFePO4).

●Features: Consider additional features like balancing, temperature sensors, or communication protocols (e.g., CAN, Bluetooth).

●Physical Size: Ensure the BMS fits within your battery pack or device.

Consult the battery and BMS datasheets, and if unsure, seek advice from the manufacturer or a professional.

How do I wake up my BMS battery?

Some BMS-protected batteries enter a sleep or low-power mode to prevent damage when deeply discharged. To wake up the BMS, you may need to:

●Apply a small external voltage to the battery terminals to bring the voltage above the BMS activation threshold.

●Use a specialized charger or device designed to reset or activate the BMS.

Consult the battery or BMS manufacturer’s instructions, as the procedure varies by model.

How do I reset my BMS battery?

To reset a BMS:

●Disconnect the load and charger

●Wait 10–30 seconds

●Reconnect the charger to trigger reset

●In smart BMS systems, use the app’s reset feature

Some advanced BMS units may require hardware reset buttons or software-level reinitialization.

How do I update my BMS battery?

High-end BMS allow firmware updates for bug fixes or new features:

●Connect via USB, Bluetooth, or CAN bus.

●Use the manufacturer’s software to upload updates.

Follow instructions carefully to avoid bricking the BMS.

Conclusion

In summary, a Battery Management System is indispensable for lithium battery packs, ensuring safety, optimizing performance, and extending battery life by continuously monitoring and managing the battery’s critical parameters. Using a BMS is essential for any lithium battery application to prevent hazards and maintain reliable operation. If you’re unsure about the right BMS for your application, always consult a battery expert or the manufacturer. As a globally leading manufacturer of rechargeable LiPo batteries, Grepow possesses advanced in-house capabilities for BMS research, development, and design. We can develop and customize BMS solutions tailored to specific customer needs, whether for high-capacity 24S drone batteries up to 84Ah or for ultra-thin batteries measuring just 0.5mm thick. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

LiPo battery vs LiHV battery: what’s the difference?

2025-07-16 -

Building an FPV Drone: A Deep Dive into the Technology

2025-06-30 -

What is an 8S LiPo Battery?

2025-06-20

Related products

-

Tattu Agricultural Drone Battery

-

Tattu Plus Series Drone Battery

-

Tattu 4.0 18S Lipo 30Ah 68.4V Smart UAV Drone Battery