Laser Welding to Nickel

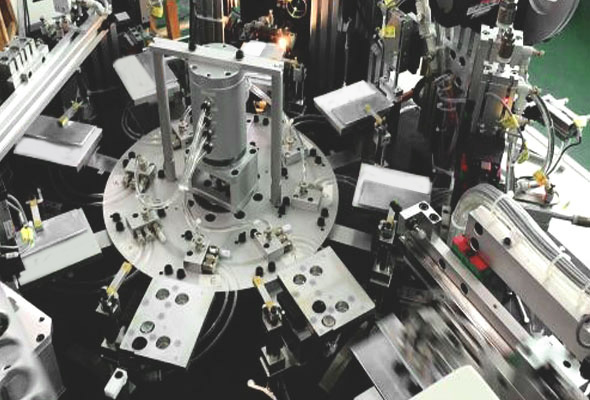

Traditional thermit welding needs many working stations, waste on resources, difficulty in operation. In addition, traditional soft case batteries cathode tabs welding to nickel, need to cut coil stock nickel strips into fixed length pieces, then worker one hand takes the cell, another hand takes nickel plate, put them to laser machine to fix and weld by eyeballing, any redundant nickel strips in the welded tab will be cut by workers. Above operations are completed by manpower only, it's low efficiency, bad consistency, quality is not guaranteed. In new welding nickel procedure, Grepow adopts new laser welding technique to nickel, laser welding has quality guarantee, hardly exist any welding headwear and tear, intelligently adjust the machine in one key, switch size rapidly and automatically. Testing data shows those laser welding cells are more concentrated on internal resistance, discharge rate, and other important indicator data, also higher consistency.